Telme

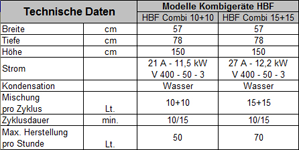

Telme HBF Kombigeräte

HBF COMBI are ideal for making ice cream with a special recipe, such as, for example,

Chocolate in different versions: white chocolate, milk chocolate, dark chocolate, bitter chocolate, etc.

– Heating boil with a capacity capable of preparing large quantities for each type or a milk base of a syrup for the fruit ice.

– Allow separate heating and cooling devices simultaneous heating and freezing.

– You are preparing higher volumes than other devices same rated power.

– Efficient and fast processing cycles.

– increase in volume by about 40% and considerable Creaminess of the ice cream.

– The product is output efficiently and completely.

– Ice cream with optimal structure and spreadability.

– Large storage space for trays and containers. she is and is equipped with a lattice that allows the Bottom of the bowls or containers keeps clean.

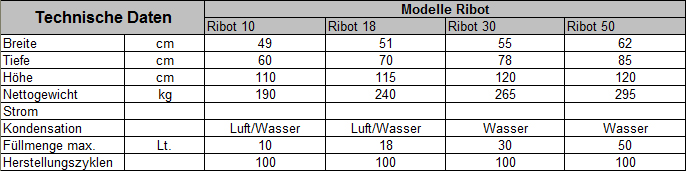

Telme Ribot

– Rühren, Mischen, Aufschlagen, Schneiden, Zerkleinern, Kneten, Erwärmen, Kochen, Erhalten, Temperieren, Pasteurisieren, Kühlen, Schockfrosten und Gefrieren von Lebensmitteln: Brot, Nudeln, Reis, Fleisch, Fisch, Gemüse,

dazu flüssige, cremige und teigartige Produkte

– Erwärmung über zirkulierende wärmeleitende Flüssig- keit erlaubt punktgenaues Kochen und verhindert ein Anbrennen des Produktes.

– Schnelle Wärmeübertragung, da das Produkt im Zylinder gemischt wird.

– Präzise Temperaturkontrolle sowohl beim Erwärmen als auch beim Abkühlen.

– Langes Halten einer spezifischen Temperatur

– Schnelles Kochen und Abkühlen, dadurch reduzierter Gewichtsverlust und Beibehaltung der Farben sowie des natürlichen Aromas und Geschmacks der Lebensmittel.

– Schnelle Senkung der Temperatur des Produktes, das im Zylinder gemischt wird

– Schnelle automatische oder manuelle Zyklen für erhöhte Wirtschaftlichkeit.

– und vieles mehr!

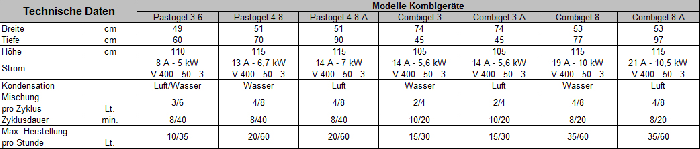

Telme Kombigeräte

PASTOGEL

Multilingual display, 14 pre-programmed cycles and 10 programmable production cycles for your own recipes. Adjustable times and temperatures make it possible to meet every working requirement.

Vertical cylinder: easy to fill, very useful in the ice cream parlor.

Efficient stirring: the ice cream is raised and falls again. Walls and bottom of the cylinder are used to transfer the entire available cooling capacity. Self-diagnosis simplifies technical customer service.

CombiGel

With two vertical cylinders, heat and refrigeration cycles can be applied simultaneously or successively to produce or pasteurize ice cream, sorbet and granita.

Time cycle: for the desired structure and consistency of the ice cream.

Temperature cycle: allows the consistency of the final product to be obtained even with different batches.

Preservation at the end of the cycle: as a work facilitation.

Display of operating time: for maintenance planning.

Self-diagnosis: helps the customer service technician.

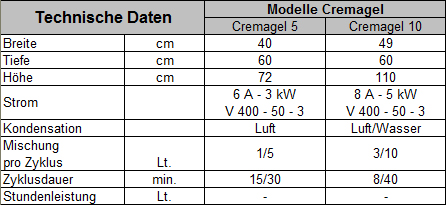

Telme Cremagel

CREAMAGEL 5 e CREMAGEL10

Multi-purpose machines that prepare all classic creams and other confectionery specialties

and the various ice cream mixtures pasteurize and freeze.

They have 3 specific programs:

P1C automatic cycle for warm preparations

P2F automatic cycle for cold preparations

P3C automatic cycle for hot and cold preparations.

Variable temperature range from + 99 ° C to -15 ° C. The various temperatures are adjustable and the heat treatment in a single cylinder ensures maximum hygiene.

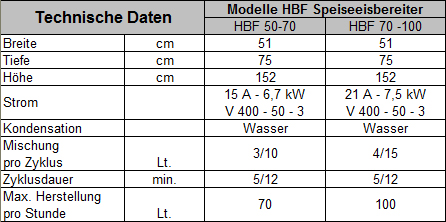

Telme horizontale Speiseeisbereiter

DIFFERENTIAL CHARACTERISTICS AND SPECIAL FEATURES OF THE HORIZONTAL LEGS HBF

– higher yields of preparations compared to other machines of the same performance spectrum

– performs efficient and fast working cycles

– ensures an average volume of 40% higher volume and a distinct creaminess of the ice

– ensures efficient and complete product output

– produces a dry ice with structure and optimum pestle propertys

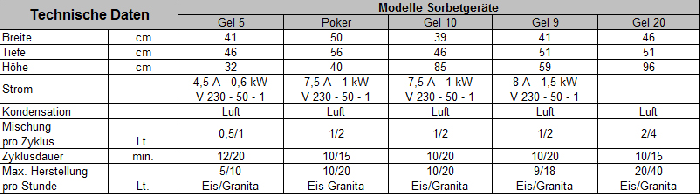

Telme Sorbetgeräte

GEL 5, POKER, GEL 10, the ice cream machines with manual

Removal, have electronic control and are extremely easy to use:

– Depending on the model, the fixed amount of the batch is poured into the machine.

– Select the cooling time

– Start the stirrer and the compressor

– Taste pastes are added before the end of the cycle.

– A tone indicates the end of the cycle, the ice cream can be removed manually

GEL 9, GEL 20, ice cream and sorbet machines with automatic removal, low space requirements and extremely simple operation.

– Fill the batch according to the model

– Select cooling time (minutes)

– Switch on agitator and compressor

– Add pastes before the end of the cycle

– At the end of the cycle, the ice cream produced is automatically removed

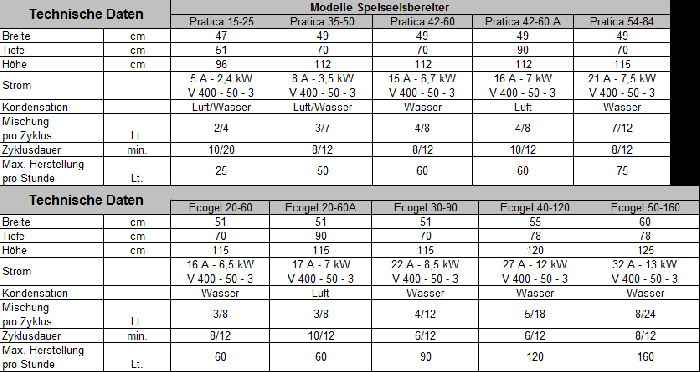

Telme PRATICA, ECOGEL

PRATICA models, like all ice cream makers from TELME, have a vertically arranged cylinder. Its special feature is the efficient mixing of the resulting ice cream. The agitator presses the mass upward, then it falls down again due to the gravity. With the temperature cycle you always get the same results, even with different batches. The temperature of the ice cream is indicative of the percentage of frozen water, which in turn affects the shelf life, and the ice cream can be dispensed a few minutes later, as the machine automatically preserves the ideal state Rotating direction and doubling the speed of the agitator ensure an optimal removal of the product.

ECOGEL, ice cream maker with high cooling capacity, which is fully utilized thanks to the movable scraper elements, since these are pressed against the cylinder walls by the ice mass. The replacement of the scraper elements is simple and cost-effective.

In order to facilitate the work of the user, there are the following preset programs:

– 6 temperature programs from -7â ° to -12â ° C.

– 3 time programs from 7 to 11 minutes.

– 1 program for Granita.

– 1 program for granita with coffee flavor and following, adjustable programs.

– 2 temperature programs.

– 1 time program.

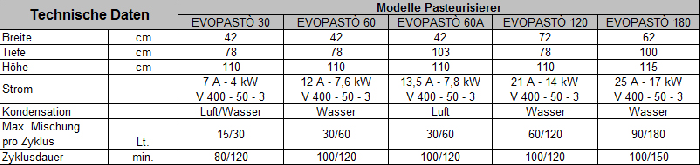

Telme Pasteurizer

EVOPASTO, the automatic pasteurizer of TELME, made of high quality materials and components, preserves the organoleptic characteristics of the ingredients. For the indirect thermal treatments, a food-like, thermolitizing liquid is used.

This results in further advantages:

– higher yield of the aromatic substances.

– Hydration of the stabilizers and the dry mass.

– dissolving the sugars.

– liquefaction and uniform suspension of the fats in the mixture.

– A more stable emulsion.

The thermal treatment of the mixture consists of heating to 85 ° C. and subsequent cooling to 4 ° C. The cycle must be carried out quickly. The lid can be opened to add ingredients at any time. All parts that come into contact with the product are completely removable for daily maintenance. The dispensing tap with built-in wash system ensures perfect and lasting hygiene after each removal and at the end of the operation. The devices are equipped with “intelligent” control, which repeats the pasteurizing cycle, if necessary, in case of power failure.

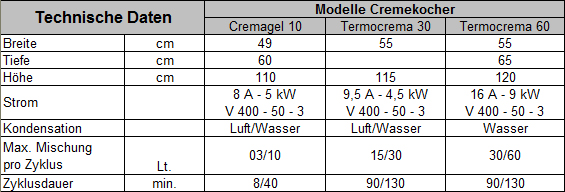

Telme Cream cooker

TERMOCREMA

– Automates all necessary activities that require strength, effort and time;

– ensures optimal processing hygiene

– Mixes, mixes and kneads with pre-programmed temperature, time and speed the following ingredients: milk, cream, dried milk, flour, fruits, sugar, dextrose, eggs, emulsifiers, stabilizers, etc., necessary for classic creams, confectionery specialties, gastronomic preparations And to prepare various mixtures for ice-cream specialties

– Heated, sterilized and cooked: dissolves fats and chocolate, softens solid parts, eliminates the majority of bacteria-inducing bacterial flora and makes superfluous water evaporate

– Tempered bitter, milk and white chocolate

– Cooling, shock cooling and preservation: completes the pasteurization, whereby the growth of the remaining bacterial flora is stopped (“microbiostasis”). The manufactured products are maintained at a temperature which complies with the guidelines

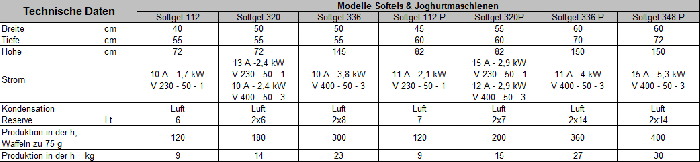

Telme Softeis and yoghurt machines

SOFTGEL

Main functions

– Preserve the mixture at 4 ° C.

– Mixes and freezes. Blend air with the ice cream mix and turn it into ice cream.

– Preserves ready-made ice in the freezing cylinders.

– Immediate delivery as required.

Use:

– Sale of soft ice cream and frozen yoghurt.

– Preparation and garnishing of ice dishes and desserts.

– Filling ice cream cups.

These models are operated by charge valves.

SOFTGEL P

Anyone can sell with the popular and profitable

“Soft ice cream”.

Softgel 112 P, with one cylinder for a soft ice cream, Softgel 320 P, Softgel 336 P and Softgel 348 P with two cylinders for two varieties and a mixed variety of soft ice cream.

These models work with rotary vane pumps, which guarantee a considerable volume increase. The blended air allows a particular structure of the product to be dispensed, both soft ice cream and yoghurt are characterized by exceptional creaminess.

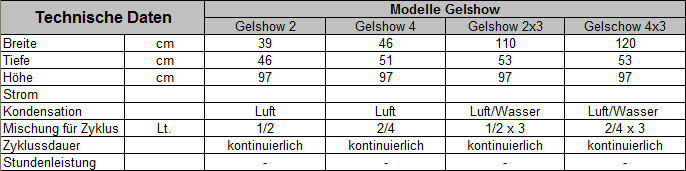

Telme Gelshow

SPECIFIC CHARACTERISTICS AND ADVANTAGES OF THE CONTINUOUS SPEAKING MACHINES GELSHOW OF TELME

– Lower acquisition costs against other preparation and sales solutions.

– Little need for space.

– The work area and sales cabinet are not required.

– Very simple operation and handling, which do not require special training.

– The machines allow an excellent visibility of the product during preparation.

– Continuous mixing and cooling in order to always obtain finished ice cream.

– It is possible to add various ingredients at any time.

– Two freezing temperatures and a preservation temperature are adjustable.

– Safety magnet on the cover.

– The finished ice cream is delivered directly from the cooling cylinder for consumption.

– Hygienic, easy to clean.

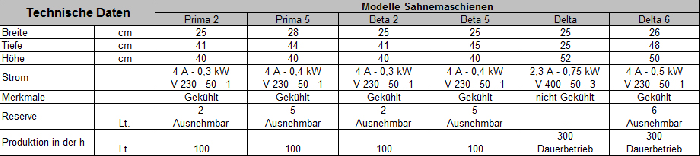

Telme Cream machines

DELTA, the cream machine for continuous operation, characterized by its rounded design and rotary slide pumps with high performance and high pressure. These machines offer a large volume increase and produce large quantities of whipped cream with firm and stable structure. The output is by manual control, continuously or in adjustable quantities. The machines were manufactured for large shops, production sites and industrial use. They enable continuous production and are equipped with various accessories for filling and decorating.

The double impact tube made of stainless steel produces an unusually strong volume increase of the whipping cream with a creamy and homogeneous structure.

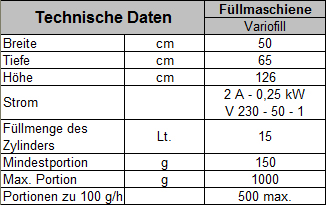

Telme fill machines

A good alternative to high-priced dosing machines, which often can not process either ice cream or ice with solid pieces. Ideal for ice makers who want to make cups and other ice packs. Also suitable for other foodstuffs. Installed on a rolling base, easy to move. Equipped with all possible protective devices, therefore also safe in case of an application fault.

The automatic cleaning of the cylinder and the dispensing tap facilitates the application and guarantees hygiene

VARIOFILL, compressed air filling machine for cups and other leverage packs.

It makes it possible to work with self-produced ice-cream, the max. 10 mm large pieces of fruit, dried fruit, torrone, etc. The capacity of the cylinder is 15 l ice, the output speed and pressure can be adjusted according to the product.

For easier use with hand or foot operation.

The machine can work with different products of different consistency, possible portion sizes of 100 to 1000 g.